Research projects with our academic and corporate collaborators are geared toward developing cost-effective processes for recovery of industrial and biopharmaceutical products derived from a variety of raw sources such as corn, rice, sugarcane, Lemna minor, bacteria and microalgae.

Our current focus include-

We are exploring extraction, pretreatment and chromatography methods to develop an optimized downstream purification process. This project aims at producing a stable, active and highly purified recombinant protein from recombinant E.coli and Chlamydomonas reinhardtii lysate.

We are exploring extraction, pretreatment and chromatography methods to develop an optimized downstream purification process. This project aims at producing a stable, active and highly purified recombinant protein from recombinant E.coli and Chlamydomonas reinhardtii lysate.

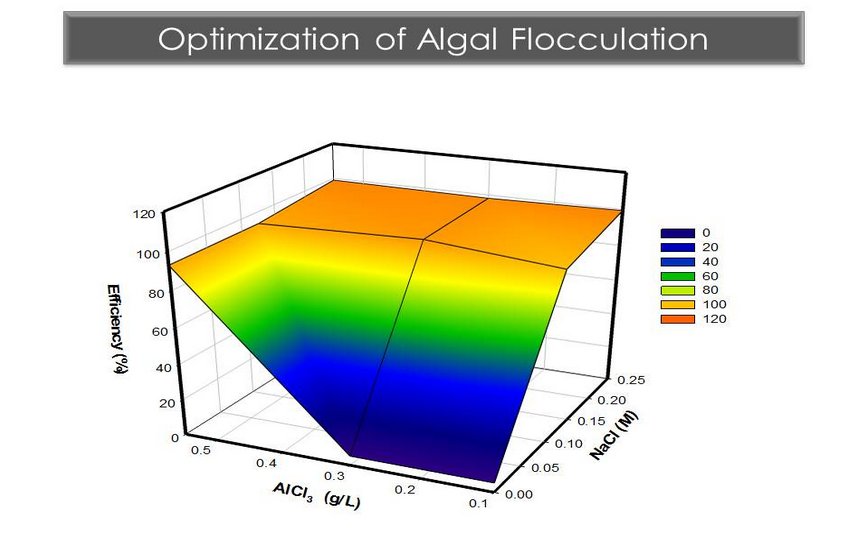

Various techno-economic analyses have confirmed that algal production platform won’t be economically feasible unless multiple high-value compounds are co-extracted. We are designing processes to enhance extraction of not only anti-oxidants and nutraceuticals such as lutein and chlorophyll, but also high-value functional protein concentrate for food products. During extraction of products, various parameters that determine their market value, such as the structure, purity and functionality are being analyzed.

Various techno-economic analyses have confirmed that algal production platform won’t be economically feasible unless multiple high-value compounds are co-extracted. We are designing processes to enhance extraction of not only anti-oxidants and nutraceuticals such as lutein and chlorophyll, but also high-value functional protein concentrate for food products. During extraction of products, various parameters that determine their market value, such as the structure, purity and functionality are being analyzed.

The economic and technical feasibility of protein products from the microalgae species Chlorella vulgaris is being evaluated. We aim to develop an extraction and hydrolysis process that maximizes economic value of algae feedstock by optimizing unit operations efficiency and co-extracting other high value products.